Product Details

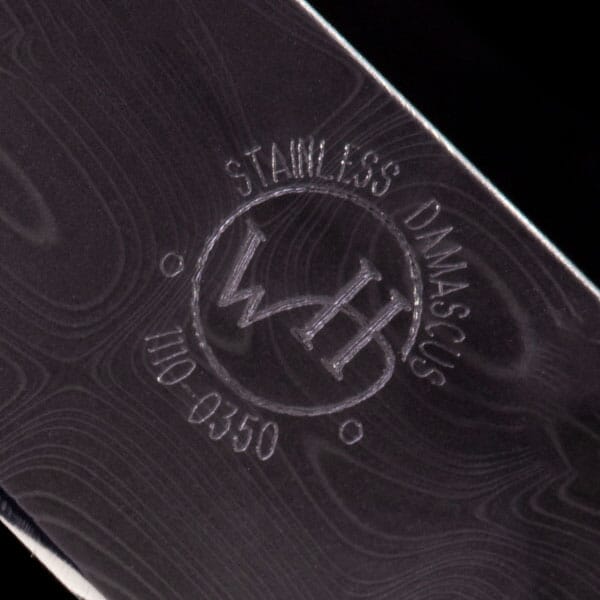

The Gentac ‘Saturn II’ features a light and resilient frame in aerospace grade titanium, and anodized blue titanium pocket clip. The blade is extra-strong VG-10 core 'Wave' damascus; the one-hand button lock and the thumb stud are stainless steel. An exceptional design that offers rigorous performance in a sleek, comfortable knife, the ‘Saturn II’ features some of the hi-tech and forged metals that are the hallmark of William Henry's collections; a distinctive personality statement to be worn and used for a lifetime.

Product SKU: B30 SATURN II

Materials

Features & Specs

One-hand button lock system

Integrated titanium pocket clip

Wood presentation box

Dimensions:

Blade 3.25" (82.5mm)

Handle 3.80" (96.5mm)

Overall open 7.00" (177.8mm)

All William Henry knives feature a unique serial number which is engraved into the blade to assure the authenticity and lifetime traceability of the product